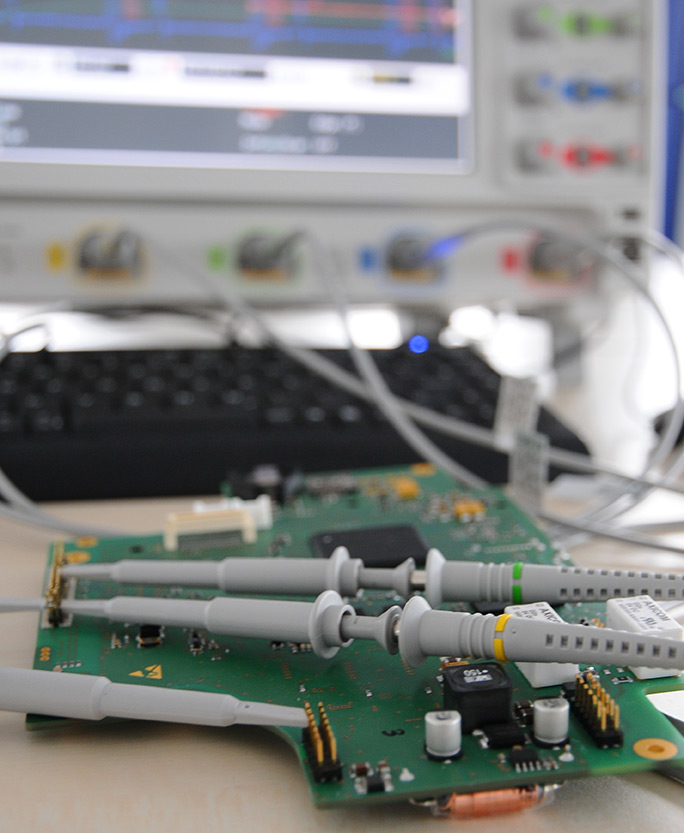

Electronics development

Our goal is to achieve excellence in electronics development so that our customers can successfully position their products in the market. We offer:

- Customized solutions from experienced experts

- Highest safety standards for customer projects

- Economical implementation of development processes through efficient and lean structures

Experience and expertise

Our know-how is cross-product and cross-industry and includes experience from numerous projects.

Over the years, we have developed a comprehensive library of proven modules and features that we can apply to different projects. This allows us to offer our high-quality development services in an even more time- and cost-efficient manner.

Another strength is our ability to easily transfer what we already know to other industries.

In addition to our development services, our customers benefit from in-house production and EMC testing if required. Due to the direct feedback from both departments, we have a wide range of experience with regard to EMC and production-oriented development.

Security for customer projects

Sensitive handling of development data is a matter of course for us. We ensure that every project is carried out under the highest possible secrecy and guarantee maximum security for your data. Since our company acts as a development and production service provider and does not sell own products, conflicts of interest are excluded.

We ensure the timely completion of customer projects at all times. Our interdisciplinary team consists of several experienced employees. Changes in the project scope or staff absences on our part can thus be covered at any time.

Extract from our development services

Our development services and consultations can be booked individually or holistically.

Do you have questions about our electronics development? Our employees will be happy to help!

Hardware

Concept creation

In the first step, we create a concept based on customer requirements and define the development process. If required, we offer comprehensive consulting, for example on standards and guidelines, modularization, cost-efficient production and long-term availability.

Simulation

Circuit parts are simulated before implementation, taking into account different parameters.

Initial sample inspection

If necessary, we carry out iteration loops.

Initial samples can either be manufactured in our production under series conditions or provided by the customer.

Component research

The technology of components is constantly changing. Therefore, we regularly inform ourselves about the state of the art of parts, components, applications and about the latest developments on the semiconductor market. Based on this, we research components that are optimal for the function, cost and producibility of the device.

Throughout the product life cycle, we provide information on product changes and discontinuations as needed.

Printed circuit board layout

Rapid Prototyping

Using the rapid prototyping process, we produce prototypes true to the original in a short time. The basis for rapid prototyping is in-house electronics production, clearly defined processes and two 3D printers for the short-term creation of mechanical components.

Circuit diagram creation

Testing printed circuit board layout

Among others, we consider the following criteria:

- Signal quality

- Power supply

- Thermal management

- Electromagnetic compatibility

- Efficiency of production

- Cost saving possibilities

Software

Firmware for microcontrollers

- Software for control, regulation, evaluation and communication.

- Selection of suitable microcontrollers based on space situation, performance and power requirements.

Applications

- PC applications for all common operating systems (Windows, Linux, Mac OS)

- (Web) apps for smartphone and tablet (iOS and Android)

Bootloader

Possibility to update and upgrade the firmware after the product has been shipped, without sending in the device or notifying a service technician.

(Web) apps

- for smartphone and tablet (iOS and Android)

- for control and visualization of states of the electronics

- Creation of design and operating concept

- Implementation and test

Real-time operating system/RTOS

- Operating system in electronic data processing that can be used to meet real-time requirements of applications.

- Predictable timing of system calls.

- Predictable response times to events.

- Used where exceeding maximum response times causes immediate damage.

mechanics

Concept creation

Dimensioned drawing

Feasibility check

Initial sample inspection

If necessary, revision loops are carried out.

Initial samples can either be manufactured in our production under series conditions or provided by you.

Konstruktionsarbeiten 2D/3D

Project Management

Concept creation

Interface coordination

- Interfaces internally and with external partners and service providers are precisely defined at our company.

- There is no effort for our customers due to communication with external project participants.

- No loss of time and information.

Product support

We support customer products as needed throughout the product life cycle.

Individual consulting

Specifications & Requirements

This must contain, among other things, the following information:

- Description of the desired functions and technical features

- Functional diagram and type of detection

- Product design specifications, e.g. colors, shape, materials

- Standards to be followed

- Certifications sought

- Application

- Desired documentation of the development result

- Desired production documents

- If applicable, prototype production and tests to be carried out as well as documentation

- Software functions

- Handling of expected error cases

Cost optimization - component selection

Standards and guidelines

Cost optimization - manufacturing process

Cost optimization - Design

Advantages

Cross-industry expertise

time efficient

We do this

It doesn’t matter whether you already have finished requirement specifications and specifications

or a first rough idea – we take care of your project.

Contact us via vertrieb@baudisch.de and we will get back to you immediately.

Baudisch Electronic GmbH

Im Gewerbegebiet 19

73116 Wäschenbeuren

Newsletter subscription

Baudisch Electronic GmbH

Im Gewerbegebiet 19

73116 Wäschenbeuren