SMD assembly

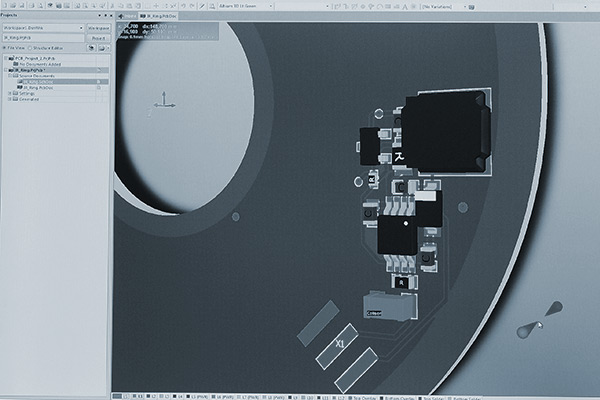

SMD assembly of printed circuit boards

SMD (Surface Mounted Device) assembly has been an integral part of our service portfolio for over 25 years, as it is the best method for dense, precise and cost-efficient PCB assembly.

Our high-end machinery is one of the most modern and powerful on the market. Due to the perfect interaction of the SMD line participants, we enable PCB assembly at the highest level.

The innovative approach of our SMD line was the reason for the prestigious trade magazine Productronic to publish a detailed user report about Baudisch Electronic.

SMD production at Baudisch

Quality

Our standard is flawless PCB assembly for maximum quality of the final product.

We rely on our high-performance and specially configured SMD production line and ISO-certified quality management. Each line participant of the SMD production is designed for optimal results.

All printed circuit boards are provided with a unique code, which ensures complete traceability of all batches and the traceability of all process steps.

Clean solder paste printing is crucial for a perfect soldering result. A camera system in the stencil printer enables precise alignment of the stencil to the circuit board. In addition, automatic cyclical cleaning of the paste stencil ensures consistently high print quality.

The integrated 3D solder paste inspection checks the solder deposits applied to the PCBs before assembly. If an inaccuracy is detected, the PCB is removed.

The 6 Fuji SMD pick-and-place machines are highly productive and assemble printed circuit boards with an extremely high positioning accuracy.

In the reflow oven, the soldering profile is adapted to the PCB design, the solder paste and the components used to achieve perfect results. Soldering in a nitrogen atmosphere optimizes process stability.

Another important quality factor in SMD assembly is a PCB design suitable for production. If required, we provide support in electronics development and thus enable even more efficient assembly.

Flexibility

The highest technological standards, combined with sophisticated logistics, enable us to handle customer projects quickly and flexibly.

Our production line is designed for high-volume manufacturing, a high product mix and prototype production. Through the optimal interaction of all line participants, we achieve a high throughput and short set-up times.

Over time, we have become specialized in the assembly of unusual and very small components. This is made possible in particular by the Fuji NXT III placement machines, which are also specialized in difficult placement.

This flexibility earns our machine park a special status in southern Germany.

Advantages at a glance

Profitable even for prototypes and small batches thanks to short setup times and minimization of downtime between jobs.

Short and reliable delivery times through internal interface optimization and control processes.

Material procurement from proven and reliable suppliers.

ISO 9001 certified quality management.

Flexibility for last-minute additions and order changes.

Expert staff to provide comprehensive advice.

Numbers & Facts

| PCB formats: | |

| PCB length: | 70 mm bis 450 mm |

| PCB width: | 50 mm bis 380 mm |

| More formats on request | |

| Components: | All components available on the market can be processed; special components on request |

| Lot sizes: | From prototype to large-scale production (High Volume and High Mix) |

Numbers & Facts

LP length: 70 mm to 450 mm

LP-Breite: 50 mm bis 380 mm

Components:

All components available on the market can be processed; special components on request.

Lot size:

From prototype to high volume production (high volume and high mix).

THT assembly

In addition to the SMD process, we assemble printed circuit boards using wave and selective soldering processes.

Quality assurance

Quality monitoring measures include 3D solder paste inspection and Automatic Optical Inspection (AOI).

Request an offer now

Please contact us at the e-mail address vertrieb@baudisch.de and we will get back to you as soon as possible to work out your suitable offer.

Baudisch Electronic GmbH

Im Gewerbegebiet 19

73116 Wäschenbeuren