EMS services

Our focus is on service around the entire product development process – from development and manufacturing to packaging and logistics. All support and service offerings can be booked either as a complete package or as individual services.

Outsourcing electronics development

Outsourcing of development is especially suitable for startups, smaller companies and companies without capacity for own development.

A professional development pays off by a time and cost optimized production. Our professional development in combination with in-house manufacturing competencies guarantees an EMC- and production-compatible design.

Handling sensitive development data requires the utmost discretion on our part. We take various actions to ensure the confidential handling of customer data. If requested, we assure customers of confidentiality in writing.

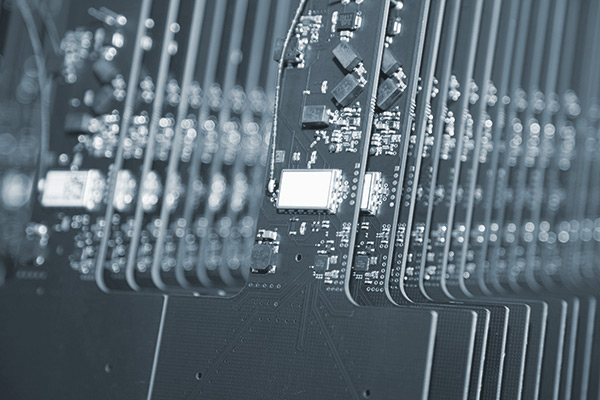

High-end electronics manufacturing

In our modern machinery in Southern Germany we manufacture high quality electronic products. Our high technological standards, combined with advanced logistics, allow us to handle customer projects quickly and flexibly.

Processes optimized according to lean management allow a cost- and time-efficient production.

We adapt our services precisely to the needs of our customers. For example, we develop a customized work system for the production of high volumes and thus achieve short throughput times and maximum effectiveness.

The all-round service

We take responsibility for the entire project

Fast time to market for your product

Same contact person and transparent procedures

Project flow

The individual steps of an exemplary EMS service at Baudisch Electronic at a glance.

You will be informed regularly about the progress of your project.

Do you have any questions about EMS services? Our employees will be happy to answer them!

1. Project start

In the first step we discuss your ideas and specify the requirements. Based on the discussion, we work out an individual project plan and define milestones.

▼

2. Development phase

The development team at Baudisch Electronic elaborates the hardware and, if necessary, the software for the product. Optionally, your already existing development concept will be checked for optimization potential and feasibility.

▼

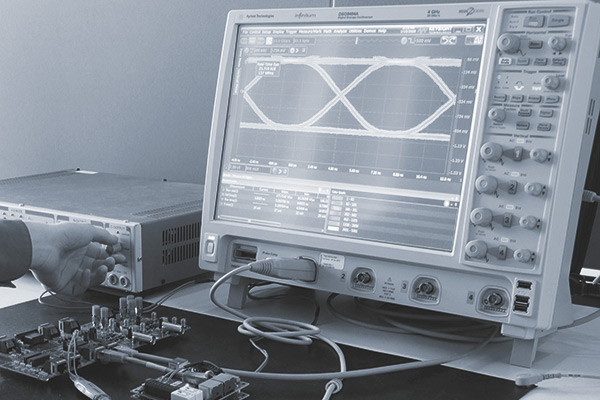

3. Prototype production and testing

Prototypes are produced. This is to be followed by

- extensive tests, e.g. EMC tests, thermal tests, climatic tests, signal integrity

- verification of requirements

- if necessary, adaptation loops

▼

4. Series production

Production of a pilot series on request.

Afterwards series production of the electronics. The material is supplied by Baudisch Electronic or by the customer.

▼

5. Test stand, assembly and shipping

In our assembly department, a complete device is created from electronic assemblies, cable sets and housings. After final steps such as function tests and customer-specific configuration, your product is packed and shipped.

▼

6. Lifecycle management

Baudisch Electronic supports you beyond production: we store spare parts, inform you in early stages about upcoming component discontinuations and about last-time-buy possibilities. On request, we ensure the rapid availability of spare parts and stock critical or discontinued components for you.

EMS services

Electronics development

With the experience from numerous projects we develop hardware and software for our customers.

Quality assurance

Quality monitoring measures include 3D solder paste inspection and Automatic Optical Inspection (AOI).

Device assembly & test stand

In the test stand, devices are subjected to electronic tests, assembled and packaged.

Request an offer now

Please contact us at the e-mail address vertrieb@baudisch.de and we will get back to you as soon as possible to work out your suitable offer.

Baudisch Electronic GmbH

Im Gewerbegebiet 19

73116 Wäschenbeuren

Newsletter subscription

Baudisch Electronic GmbH

Im Gewerbegebiet 19

73116 Wäschenbeuren

Newsletter subscription