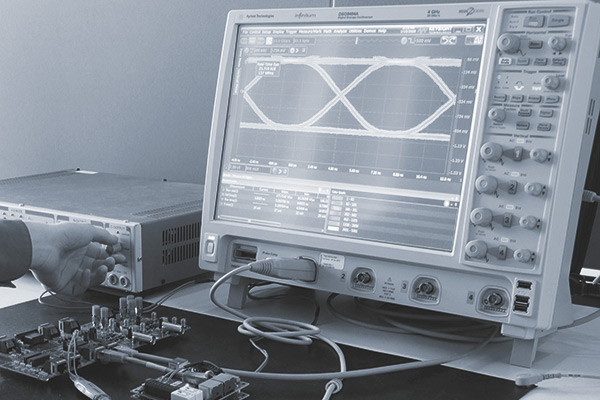

Device assembly & test stand

Our modern machinery, a high level of vertical integration and specially trained employees enable flexible and time-efficient device assembly at the highest level.

The lean workstations combine electrical testing with device assembly and are designed for both large series and small batches.

Services

- Procurement of components

- Assembly for all series sizes

- Electrical testing

- Configuration & programming of the devices

- Packaging & sealing

- Identification of optimization potential

- Lifecycle management

Advantages

✓ Efficiency

The assemblies are manufactured in-house, tested, and in the final step assembled and packaged ready for shipment. Thanks to short distances and clearly defined transitions between the individual process steps, we work particularly efficiently and economically.

The use of individually designed lean workstations enables minimum production times and a low throughput time.

✓ Reliability

Thanks to state-of-the-art technologies, standardized processes and specially trained assembly staff, we have a proven record of reproducibly high quality. Our error and return rate proves this by its low value of < 0.3 %.

Through the constant and everlasting search for optimization potential, we improve both our processes and our supply sources.

Request a offer now

Please contact us at the e-mail address vertrieb@baudisch.de and we will get back to you as soon as possible to work out your suitable offer.

Baudisch Electronic GmbH

Im Gewerbegebiet 19

73116 Wäschenbeuren

Newsletter subscription

Baudisch Electronic GmbH

Im Gewerbegebiet 19

73116 Wäschenbeuren

Newsletter subscription