Quality management

Baudisch Electronic manufactures and develops electronic products of the highest quality. Our quality management is audited and confirmed annually as part of the DIN EN ISO 9001 certification.

Our striving for the best possible quality runs through the entire company.

Development

Already in the early development phase, we pay attention to an EMC- and production-compatible product design and carry out appropriate tests.

Purchasing

- We purchase top-quality bought-in parts.

- Large network of proven and reliable suppliers.

- Regular auditing and evaluation of our suppliers.

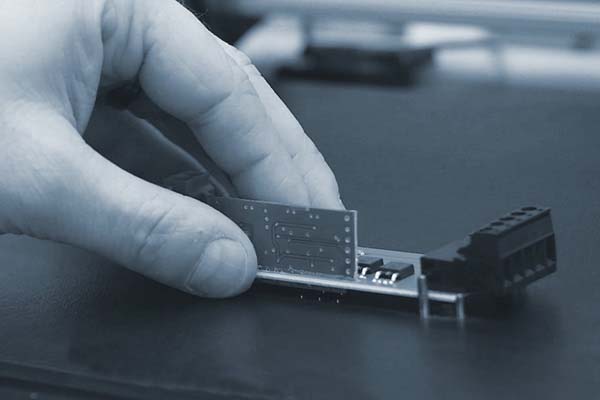

Production

- Modern machinery from top manufacturers for fast and precise production of customer products.

- State-of-the-art inspection technologies for quality assurance, including 3D SPI in the SMD production line, optical (e.g. AOI, Automatic Optical Inspection) and electrical inspection.

- Special microscopy for BGAs enables optical inspection of the soldering area between BGA and PCB.

- Complete traceability of the assemblies.

- Assembly by trained specialists.

Quality Management

✓ Continuous improvement process

Consistent identification, avoidance and elimination of errors.

✓ DIN EN ISO 9001 certification

Our high quality standard is checked and confirmed annually within the framework of the DIN EN ISO 9001 certification.

✓ Low error rate

Thanks to state-of-the-art production testing technology and specially trained employees, we keep our error rate constant at

< 0,3 %.

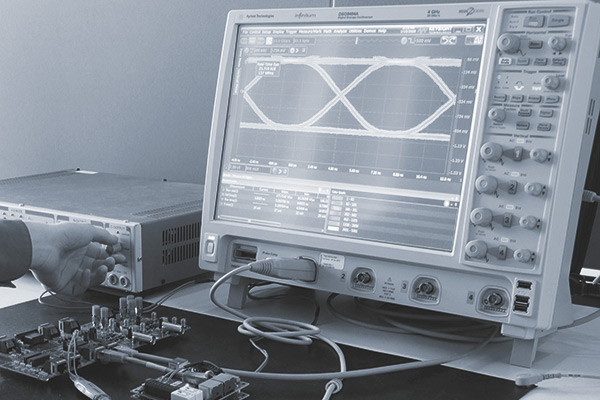

EMC laboratory

In the EMC laboratory, we test our customers’ devices for electromagnetic compatibility.

Electronics development

With the experience from numerous projects we develop hardware and software for our customers.

Request an offer now

Please contact us at the e-mail address vertrieb@baudisch.de and we will get back to you as soon as possible to work out your suitable offer.

Baudisch Electronic GmbH

Im Gewerbegebiet 19

73116 Wäschenbeuren

Newsletter subscription

Baudisch Electronic GmbH

Im Gewerbegebiet 19

73116 Wäschenbeuren