Precision in the smallest space

Leiterplattenbestückung mit Bauteil 01005

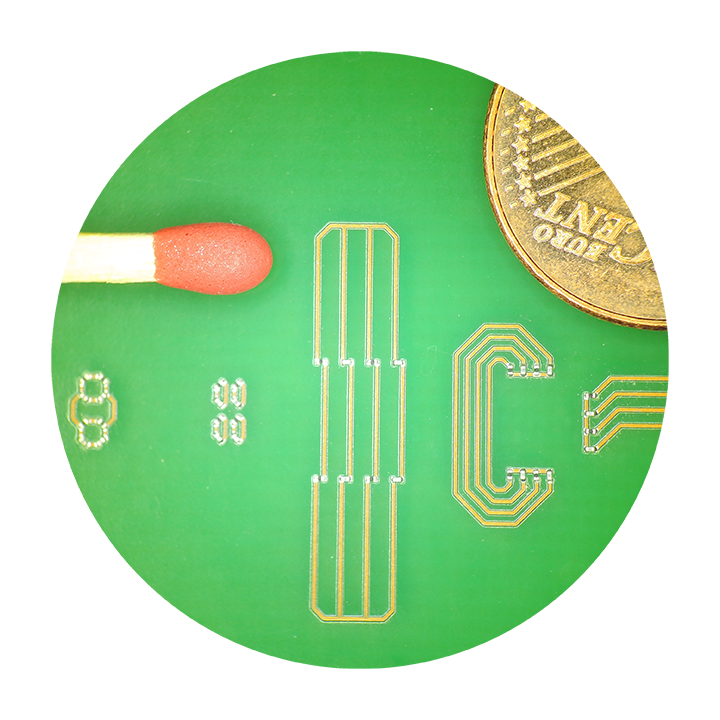

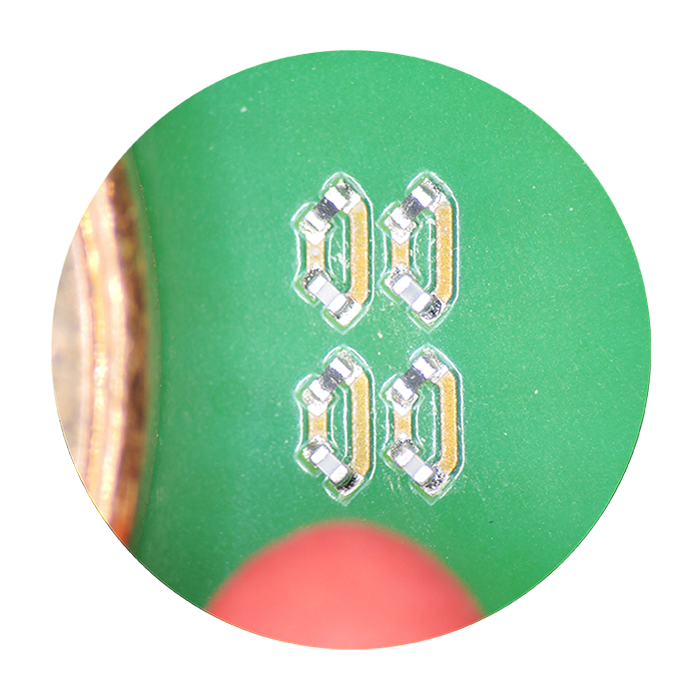

Um die optimale EMS-Dienstleistung zu bieten erweitern wir konstant unsere Expertise und unser Equipment. Seit Neuem bestücken wir Leiterplatten mit Bauteilen der Bauform 01005 und können so noch komplexere Kundenprojekte in reproduzierbar hoher Qualität umsetzen. Mit einer Größe von nur 0,4 mm x 0,2 mm x 0,2 mm ist Bauform 01005 eines der kleinsten auf dem Markt erhältlichen Bauteile für die SMD-Bestückung.Baudisch Electronic is one of few EMS service providers in Germany that assembles design 01005 in high and reproducible quality.

PCB assembly with very small components is particularly demanding and must be performed with high precision in all process steps. Even minimal inaccuracies can lead to malfunctions. To ensure that we can guarantee our customers consistently high quality, all critical process steps have been checked in the work preparation and production departments and adjusted accordingly.

Paste printing

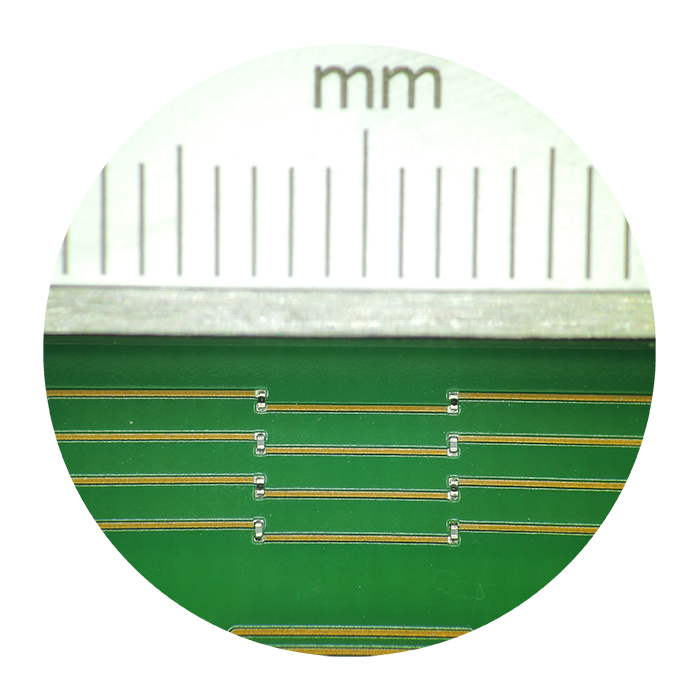

A precisely applied solder paste deposit is relevant to quality and particularly challenging when assembling printed circuit boards with design 01005. Therefore, the following measures have been defined for paste printing. Edges and unevenness in the stencil can lead to uneven distribution of solder deposits and thus to fluctuating quality. To counteract this, the solder paste stencil is given an additional electropolish to smooth the edges. The solder paste used contains a very fine grain and thus distributes itself optimally within the lasered recesses of the stencil. The design and thickness of each solder paste stencil as well as the squeegee angle are specially adapted to the very small solder paste deposit.Assembly and soldering process

The technical requirements for placement of the 01005 design were already met with the state-of-the-art NXT III placement machines from Fuji and the use of appropriately small suction nozzles. The temperature profile as well as other process parameters in the reflow oven are each specially adapted to the requirements of the very small component.Circuit board design

PCB design with design 01005 requires special background knowledge. Among other things, care must be taken during hardware development to ensure uniform conductor track connections. Also, all components must be placed on the PCB in such a way that both large and very small components are heated evenly in the reflow oven. On request, we can support and advise you on PCB design with very small components. href=”https://baudisch-electronic.de/en/ems-services/electronics-development/”>Here you learn more about our hardware and software development. Find out more about PCB assembly at Baudisch Electronic here.Baudisch Electronic GmbH

Im Gewerbegebiet 19 73116 Wäschenbeuren

newsletter subscription

Baudisch Electronic GmbH

Im Gewerbegebiet 19

73116 Wäschenbeuren

newsletter subscription