Moisture-sensitive components

Electronic components can be hygroscopic, i.e. they tend to attract moisture from the ambient air and accumulate in the plastic housing.

The trapped moisture can lead to damage of the affected component during the soldering process in SMD manufacturing and endanger the quality of the assembly.

When handling and storing moisture-sensitive components, we therefore rely on standardized processes, an automated handling system, and careful documentation.

Dangers with moisture-sensitive components

If moisture-sensitive components are heated in the reflow soldering oven during the SMD soldering process, the moisture expands in the form of water vapor. The abruptly created pressure can severely damage the affected components.

Small, barely visible cracks can occur in the housing of moisture-sensitive SMD components. In extreme cases, the sudden increase in pressure causes the casing to burst open. This phenomenon is also described as the popcorn effect.

In the case of multilayer printed circuit boards, the layers bonded together are delaminated if the pressure is too high. This leads to the defect of the printed circuit boards.

Moisture Sensitivity Classification (MSL)

Components are divided by the respective manufacturer into moisture sensitivity classes, also called MSL (MSL = Moisture Sensitive Level). The scale ranges from Level 1 (not sensitive to moisture) to Level 6 (extremely sensitive to moisture).

The MSL indicates the conditions under which the respective component must be stored and how it must subsequently be processed.

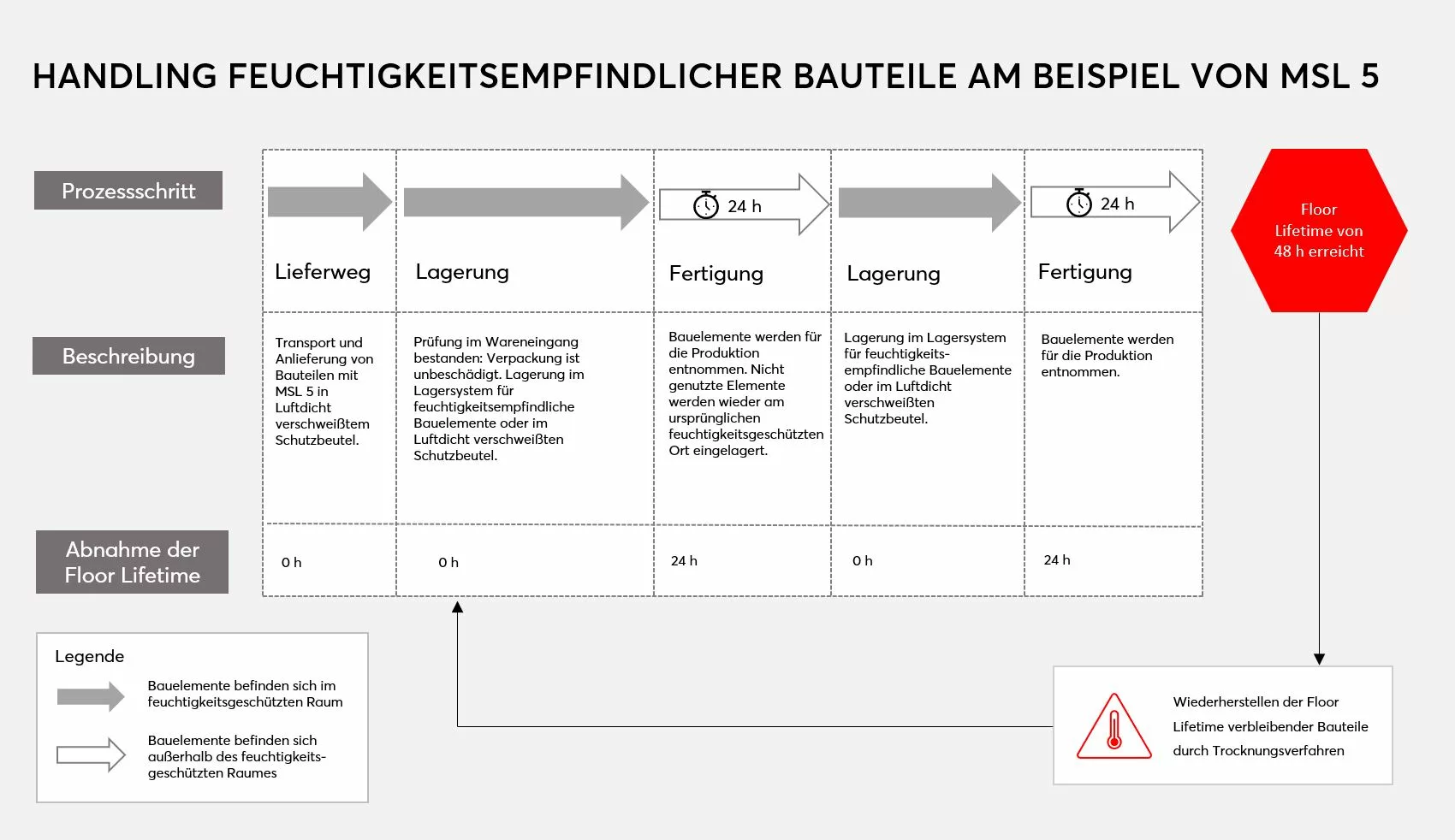

Depending on the classification, a building element may only be stored outside a moisture-protected area for a specified time. This time is also referred to as the Floor Lifetime. Once the Floor Lifetime has been exceeded, there is a risk that the component has absorbed too much moisture and will be damaged during the soldering process.

Examples:

- Components in Level 1 have an indefinite storage time without protective packaging. They absorb an uncritical amount of moisture and are therefore considered insensitive to moisture.

- Components in Level 2 can be stored outside the moisture-protected area for a maximum of one year.

- Components in Level 5 are at risk of having absorbed too much moisture after forty-eight hours outside the moisture-protected area.

Storage of moisture-sensitive components

Moisture-sensitive components must be stored in a dry atmosphere. At Baudisch Electronic, this is implemented in two ways: with a moisture-regulated automatic storage system and by means of moisture protection packaging.

Automatic storage system for moisture-sensitive components

The fully automated storage system has a separate area in which the humidity is constantly below 1%.

Moisture-sensitive components are stored here without further protective packaging.

The following information is essential for the handling of moisture-sensitive components and is therefore automatically logged and monitored by the storage system:

- Storage history

- MSL level (contains: maximum storage time without protective packaging)

- Sealing date of the manufacturer

- Manufacturer’s information on drying method, time and temperature

- Remaining Floor Lifetime

Moisture protection packaging (Drypacks)

Alternatively, moisture-sensitive components are sealed and stored in so-called drypacks to protect them from moisture. These are made of moisture-impermeable plastic and contain desiccants and moisture indicator cards for additional protection of the components.

Drying

The described hazard due to humidity exists exclusively while the temperature influence at the reflow process. Otherwise, humidity is not harmful to components. Therefore, moisture can be removed from components without any loss of quality by drying, also known as annealing. The Floor Lifetime is then fully restored.

During drying, the building element is gently heated for several hours in the drying oven provided, in accordance with the manufacturer’s instructions.

During this process, absorbed moisture slowly evaporates and escapes in a controlled manner without damaging the plastic housing.

Annealing is also used if, on delivery of moisture-sensitive goods, the protective packaging is found to be damaged. In this case, it is not possible to determine how long the components have been outside the protective packaging. Therefore, the affected components are dried as a precaution and can be stored with full Floor Lifetime.