Precise samples in the shortest possible time: rapid prototyping

Using the rapid prototyping process, we produce high-precision prototypes from CAD files in a very short time. These resemble the final product both visually and in terms of operation. The product can be experienced at an early stage of development and its haptics, handling and usability can be tested as well as, if necessary, adapted.

The investment in a prototype using the rapid prototyping process usually pays for itself many times over considering the advantages mentioned below.

All elements of the prototypes are manufactured in-house and thus without loss of time.

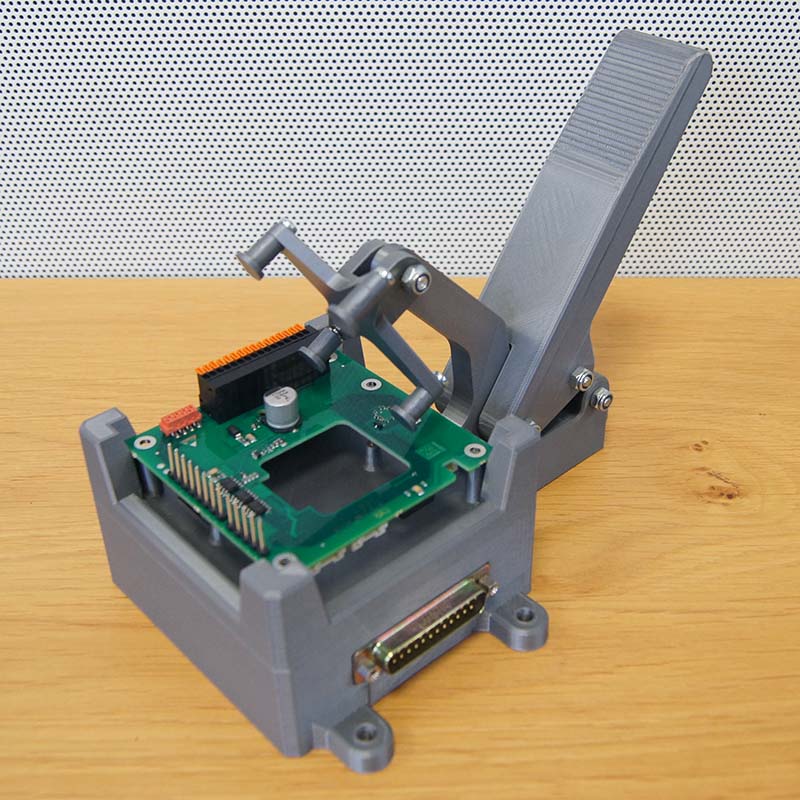

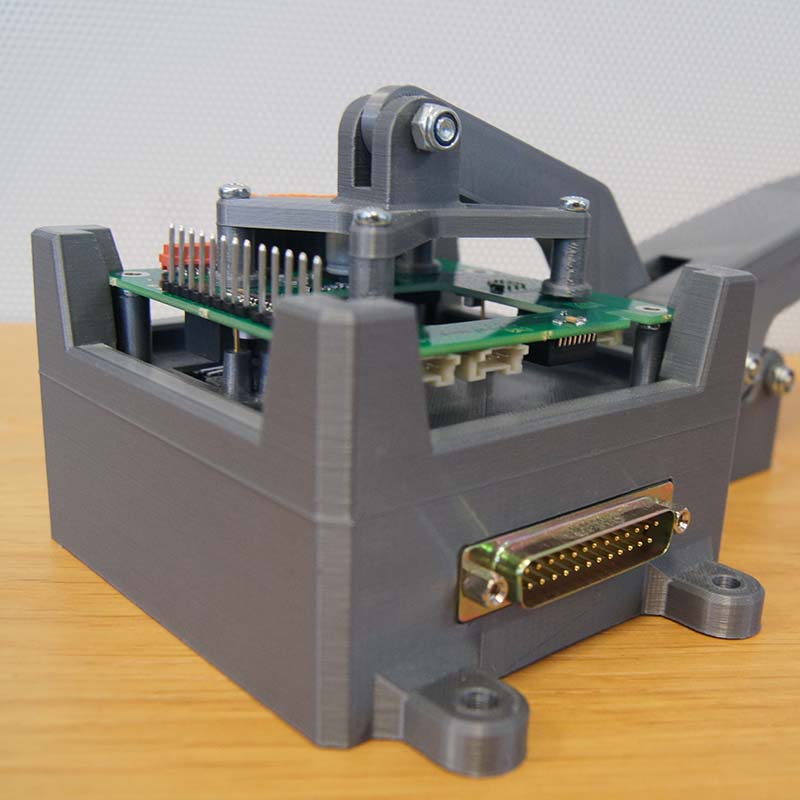

Printed circuit board assembly

As an EMS service provider, we manufacture the electronics of prototypes in our own production. The modern and flexible machinery makes it possible to produce small batches in series quality. Both SMD and THT assembly is possible.

Due to short distances and direct internal communication, there is no loss of time in this work step.

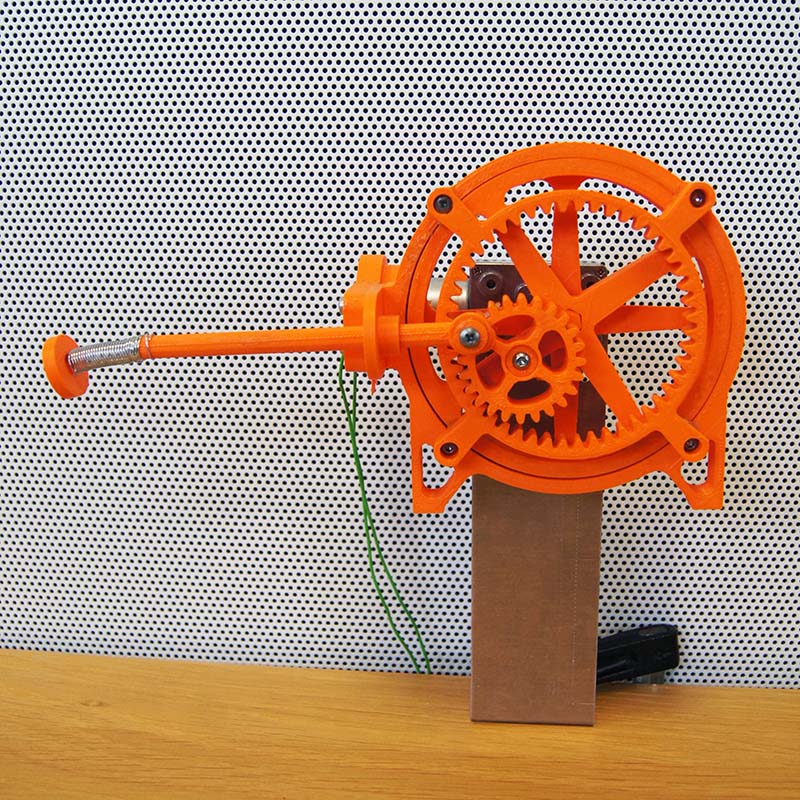

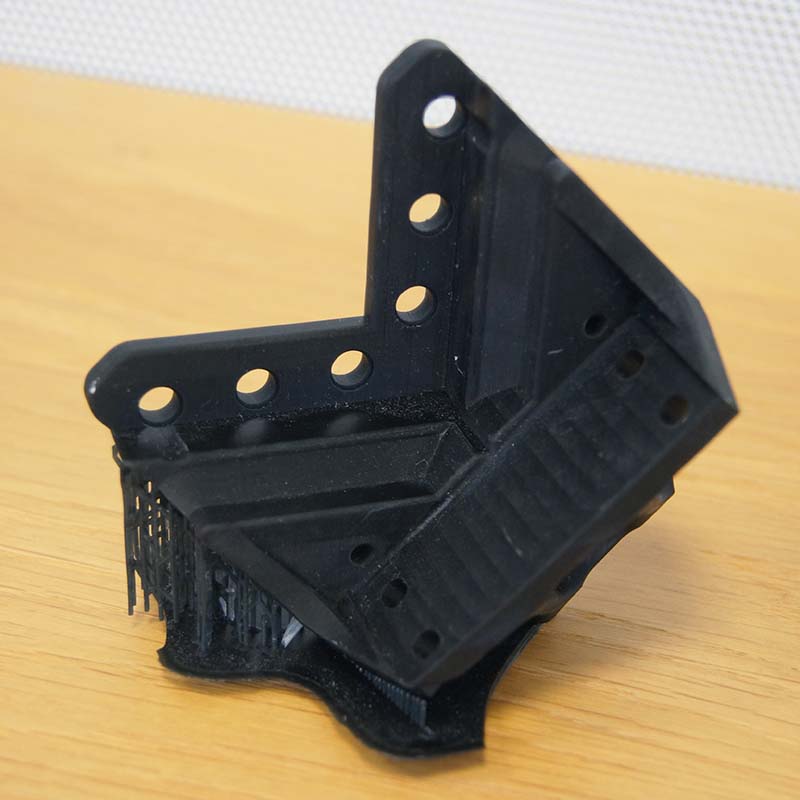

3D Printing

We manufacture the housings and the mechanical elements of a prototype using the 3D printing method. Moving mechanics, such as gear drives, are also produced using this method.

To be able to reproduce as many construction elements as possible true to the original, we use a wide range of colors and materials for 3D printing.

There are no setup costs for devices or tooling in the 3D printing process. As a result, prototype production using this method is less expensive than conventional methods. 3D printing can also be a suitable and cost-effective method for small batch production.

Advantages of rapid prototyping

Rapid availability of prototypes

In contrast to other methods, rapid prototyping offers the possibility to produce models with low time and cost expenditure. The duration of the production depends on the type and complexity of the product and is usually only a few days. Due to the rapid availability, prototypes can be used much earlier and more frequently.

Optimization of the product

Prototypes can be used to experience and thoroughly test product features at the very beginning of a development. One example of product features that can often only be fully assessed on a prototype is the arrangement and form of operating and display elements.

Due to early testing, adjustments in design and function are easily possible. Different variants of the products can be produced and the design revised according to the trial-and-error principle.

Exploitation of savings potentials

Early identification of improvement potential often leads to high savings in the later development and production phase.

Convince investors

New product ideas initially require explanation and imagination. A prototype produced quickly and to a high standard can help illustrate ideas and get investors excited about innovations.

Wide range of applications

The advantages of the rapid prototyping process can be found in almost all industries and for numerous product types.

Waste reduction

3D printing is an additive process and generates significantly less waste than conventional manufacturing processes. This conserves resources and reduces the burden on the environment.

Baudisch Electronic GmbH

Im Gewerbegebiet 19

73116 Wäschenbeuren

Newsletter subscription

Baudisch Electronic GmbH

Im Gewerbegebiet 19

73116 Wäschenbeuren